Implementation of Lean Manufacturing in Determining Time Efficiency by Using VSM Method on Production Line of PT Astra Daihatsu Motor in Jakarta

Abstract. PT ASTRA Daihatsu Motor (ADM) is the sole agent of the Daihatsu car brand holder in Indonesia that has the right to import, assemble and create a Daihatsu/Toyota branded vehicle, and related components and business in Indonesia. Lean production helps the company to become competitive with other companies, especially in terms of reducing the waste that occurs in their operations by cracking the production flow line whether the production is experiencing problems or An inefficient thing that can be replaced. This research aims to reduce waste in production in one automotive company using Lean manufacturing approach This approach is done by understanding the company overview through the flow of information and materials in the production floor by creating a Value Stream Mapping (VSM) with one of the tools in the lean concept to depict the production process flow from the raw material into finished products. The VSM is depicted with symbols that justify the activity. The Accounts are grouped in value-added and no value-added. aims to identify and analyze waste (waste of time) occurring in the production process of PT. Astra Daihatsu Motor. With the data available we can set the time of each chart in the "Assembly Plant" section and can reduce waste by decreasing the time with existing data.

Keyword : production system efficiency, lean production, value stream mapping, fishbone

A. INTRODUCTION

PT ASTRA Daihatsu Motor (ADM) is the sole agent of the Daihatsu car brand holder in Indonesia that has the right to import, assemble and create a Daihatsu/Toyota branded vehicle, and related components and business in Indonesia. ADM is a joint venture company between the Daihatsu Motor Company and Astra International which existed since 1978. In the year 1973 which became its milestone, the company gained the right to import Daihatsu vehicles to Indonesia. Three years later, Astra was appointed sole agent, importer and sole distributor of Daihatsu vehicles at Indonesia.PT Astra International, Daihatsu Motor Co., Ltd., and Nichimen Corporation jointly established steel plate pressing plant, PT Daihatsu Indonesia in PT Astra Daihatsu Motor's milestone below. With its new slogan, "Innovation for Tomorrow", Astra International is committed to always realizing innovation by delivering high-quality products that can benefit the wider community and environmentally friendly. Astra International has the vision to be No. 1 in the compact car market in Indonesia and as the main global production base for the Daihatsu/Toyota group which is the same as the Japanese factory quality standards that move them to produce compact cars Best value and provide relevant services that are essential for increasing stakeholder value and environmentally friendly and develop and inspire their employees to achieve world-level performance. Demands for increased efficiency of production systems must be offset by minimizing effortsWaste(waste). Waste is any activity that does not add value along with the flow of the process revampInputsBecome output. Efforts that can be done to reduce waste in the production process is the approach of Lean Manufacturing. The rationale of Lean Manufacturing is to identify and eliminate waste, improve quality and reduce costs and production time of Lean Manufacturing approach necessary to create a smooth production and efficiency process. This approach is a relatively simple and well-structured approach for easy to understand in order to do the efficiency process that suits the capabilities and resources of the company.

B. THEORY STUDY

Lean Manufacturing

Lean is an ongoing effort (continuous improvement effort) to eliminate waste, increase the value added by the product (goods and/services) and provide value to the customer (customer value). According to Gaspersz (2008).

Lean Manufacturing is a set of techniques that, if combined and run well, will reduce and then eliminate waste (Wilson, 2010). Waste reduction is intended so that all activities carried out in the production is a value-added activity, aiming to increase competitiveness Through effective production processes and efficient use of resources. In this research, the effort is to streamline manufacturing cycle elements to reduce waste. The approach is done using Value stream mapping.

The lean principle comes from the Japanese manufacturing industry. Lean often interpreted as a tool that can help reduce product waste, cost, time, and so on. Lean explaining that this waste reduction can be done by value Stream Mapping (VSM),5s, Kanban, and Poka-Yoke. According to Toyota Iean, not only equipment but can reduce the 3 types of wastage known as the Japanese terms that among others are Young (jobs that do not give value In addition), Muri (excessive work ), and Mura (imbalance) with the problem of finding systematic tools and techniques of Lean Manufacture.

Value Stream Mapping

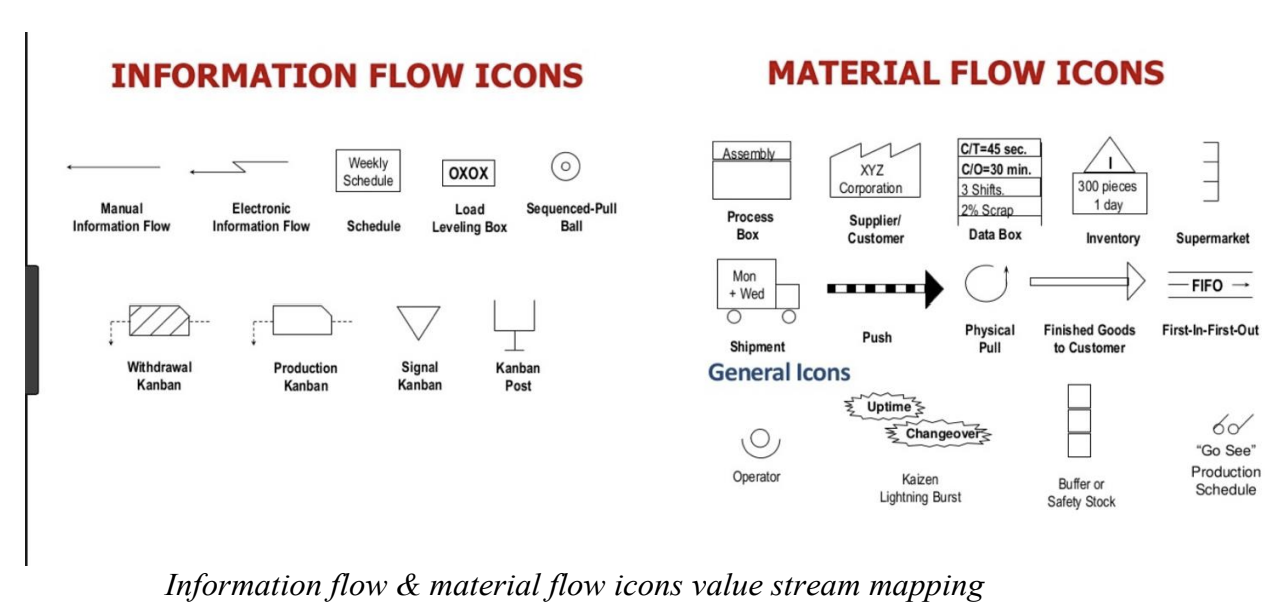

The tools are used for static visualization, analyzing and improving the process and flow of information obtained by the company to produce quality products. All the operational activities, all information obtained will be mapped in a very simple image.

Value Stream Mapping is a mapping process tool that serves to identify the flow of materials and information on the production process from raw materials to finished products. Value Stream Mappingdepicted through symbols representing the activity. Activities are grouped in value-added and non-value-added, so you can know which activities can add value and do not add value.

Fishbone diagram

Fishbone diagrams (fishbone diagrams) are analysis tools that provide a systematic way of seeing the effects and causes that contribute to the effect. Because of the fishbone function of the diagram, it can be referred to as a causal diagram, which has a basic function of identifying and organizing causes that may arise from a specific effect and then separating the root cause.

C. RESEARCH METHODS

The problem with this research is that there is an extravagance that has no added value to the product. This research was done to reduce the waste that occurred by providing a proposed improvement. After that, the model simulation is done to know how many production line capability after repair. In this research, it takes some da to do data processing.

Data Types and sources

The type of data used is quantitative whose primary purpose is to gain deeper insight into the application of Lean Manufacturing so that it can reduce waste. The data sources used are primary data, obtained through direct observation of production activities, and unstructured interviews.

Analysis tools

The analysis tool used in this research is Value Stream Manufacturing (VSM). VSM is a concept of Lean Manufacturing that shows an image of all activities or activities of value-added, as well as the unvalued, added required for the production process of raw materials until the finished product.

D. RESULTS AND DISCUSSION

The analysis tool used in this research is a Fishbone diagram Yeng useful to know The existing waste in the production. The Value Stream Mapping is useful to know the overall production process in the PRODUCTION process of assembly PT. Astra Daihatsu Motor.

1. Fishbone Diagram

Fishbone diagram is a diagram depicting the consequences of a problem. In this case, 4 parameters are used in assessing the problems that exist from the side of Methode, man, material, and machine (equipment). The following is a fishbone diagram of the type of waste (waste) in the form of the most engaged waiting time in the preparation process flow of raw material mix with the highest level of urgency:

Komentar

Posting Komentar